This is ideally what an American blade’s bevel should look like prior to honing. Note how far back the bevel goes, and its hollow form.

Customized Rinaldi Italian Machete

An excellent Italian machete from Rinaldi given a drop point and full regrind. The blade is distal tapered and fully forged construction, with a good hard, yet springy, heat treatment. The tapered stick tang is extremely stout, yet allows for a very dynamic balance that makes this heavy chopper lively in the hand.

Customized Condor Michigan Axe

A Condor Michigan axe head ground and polished to a hazy mirror finish, and a high centerline ground in. The handle is an O.P. Link shaved down to shape.

“Banko” American Pattern Scythe Blades by Igelfors Liefabrik of Sweden

The Real Douk-Douks

The French Douk-Douk knife is arguably much more famous than the Duk-Duk secret society of the South-Pacific Tolai people from which it derives its name. Photographs and drawings of actual Duk-Duk members (who acted as enforcers of tribal spiritual and civil order sometimes quite brutally) are scarce and difficult to track down amongst the throngs of images to be found of the knives that bear the name. We’ve gathered a number of images and arranged them here for those curious in knowing more about the figure behind the iconic tool.

We do not own any of these pictures. If you are the copyright holder of any of them and wish them to be removed, please let us know.

Manufacturing Scythe Snaths

A fascinating ca. 1911 account of the manufacture of wooden scythe snaths at the Fenn Manufacturing Co. of Charlotte, MI. Interestingly, the wood used for the grips of their nibs are described as being made from maple, while birch was the most commonly used wood for the task.

Young, C. (1911). Manufacturing Scythe Snaths. In The Wood-Worker (Vol. 30, pp. 30-31). S. H. Smith Company.

Vintage American Scythe–Offset Seymour Ironclad

A fully restored and tuned Seymour Ironclad swing socket snath outfitted with an Emerson & Stevens “Clipper” grain cradle blade adapted for haying use. The snath has been significantly shaved down, the nib blocks replaced with ones of improved fit (the upper one having been modified for proper interface) and new grips installed on the original nib irons. The hardware has been electrolytically de-rusted and thoroughly cleaned, the whole tool having been given a protective clear coating.

Solving the Tomahawk Handle Knob Problem

Shown here is a 350g Rinaldi “Calabria” hand axe with a modified handle. A common complaint raised regarding slip fit handles is that (despite their virtues) a knob is either small or totally absent, meaning there is little or nothing to stop the hand from slipping off the end of the handle if a loose grip is used. A simple tapered cross-pin at the end of the handle creates a removable solution to this problem.

A tapered hole was bored with a small step drill and a wooden pin, tapered to match, driven into the hole. The single-sided pin with the projection to the outside of the hand is the most comfortable and secure arrangement vs. a finger-sided or double-sided projection, and if the head must be removed from the handle for use as an independent tool the wooden pin is easily driven out so it does not obstruct the removal of the head. This provides several notable advantages over the use of a lanyard: the user’s hands may slide freely along the handle as needed to adjust grip position, the handle may still be immediately released in the event of an emergency or accident, and the pin allows the end of the handle to be tucked under a belt and have it stay there nicely if the user’s hands need to be free without setting the axe on the ground.

American Scythe Restoration: Unidentified 32″ Grass Blade

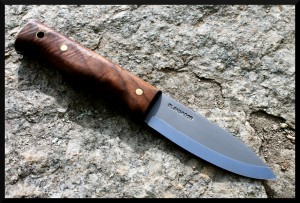

An Uncommonly Nice Bushlore!

Once in a great while we have a knife or tool come in that’s especially stunning, and this knife is one of them! Gorgeous figuring in those walnut scales. This is one Bushlore that’s dressed to impress!